TAI’s Structural Steel Services division is staffed by experienced personnel to provide steel fabrication, erection, and structural project field services support for industrial and manufacturing industries. This group works toward securing structurally specific construction projects as well as providing structural support for other SCI construction divisions and pursuing self-performance opportunities arising from TAI engineering design projects.

TAI has successfully completed fabrication, installation, and procurement projects throughout the Mid-Atlantic and Northeast. The initial focus of this new division will be self-performance of small to mid-sized structural steel projects (up to 100 tons) as well as significantly larger projects (steel and concrete) that we will continue to direct through our industry partnerships. TAI-SCI is positioned as EPC (Engineer/Procure/ Construct) Contractors offering Clients a genuine single-source for all of their structural needs.

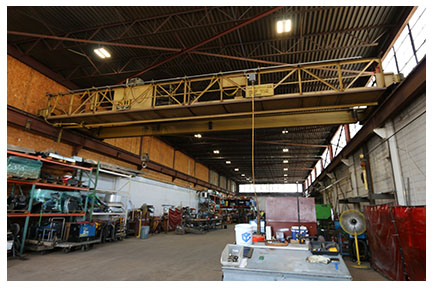

TAI-SCI’s Fabrication Shop

Our Steel Fabrication Shop is 10,000 sf with an overhead bridge crane rated at 15,000 lbs. This facility extends our engineering capabilities for customization and flexiblity in construction and enables us to work hand-in-hand with our engineers to bring designs to fruition. Specialized structures that are unique solutions to the Client’s needs, are fabricated directly from our designs and delivered to the Client. The Shop is conveniently located just off of the 695 exit in Sparrows Point, Maryland.

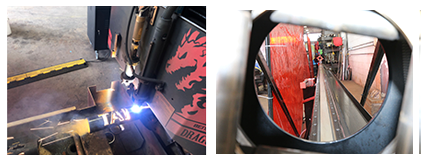

ORBIT CUTTER – ORBIMAT 180 SW

Expedites welding on piping and tubing. This intelligent power source combines the orbital welding process with state-of-the-art information and communication technology and ensures the best welding results, high efficiency and sustainable quality management. It provides centralized access to projects and parameters, intuitive operation, higher quality and safety, and shorter welding cycles and higher productivity.

TUBE CUTTER

This plasma cutter is capable of processing Tube, Pipe, Angle and Channel material up to 6″ wide and 20′-0″ lengths. Integration with design programs allow transfering designs from engineering to CAD/CAM programs and allows for cutting, marking and engraving parts fast and efficient.

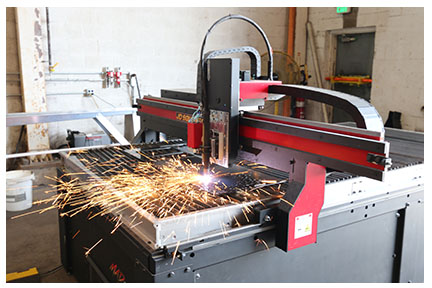

PLASMA TABLE

This 5×10 table allows cutting, marking and engraving of plate and sheet material. With a back end of CAD, CAM, and CNC software it quickly and efficiently creates parts for client projects.