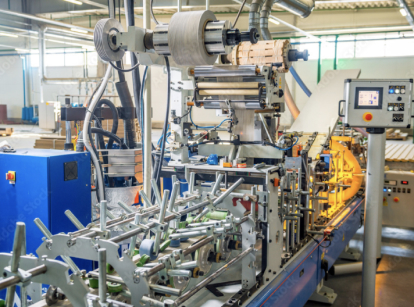

Discrete Manufacturing

From concept to controls design to programming to installation, testing, and startup, we provide the services to bring your discrete manufacturing to new levels of quality and efficiency.

We create machine control, we integrate machines into production lines, and we integrate production lines into whole factory operations. We design for your environment whether it be hazardous, washdown, clean room, indoor, or outdoor.

We work with many different hardware and software platforms to provide the control functions and operator interfaces that best serve your needs.

Our controls engineers know material handling; sequencing; sortation; motor and servo controls; web and print registration control; instrumentation; inspection devices; pneumatics and hydraulics; safety design; communications networks; data collection, historization, and reporting.

Our electrical design and programming encompass de-palletizers; bulk, liquid, part, and container conveying systems; filling machines; labelers; cappers; cartoners; case erectors; case packers; gluers and tapers; palletizers, banders, and stretch wrappers.

Machine Control

We participate in concept development and carry that through to controls design to programming to installation,

testing, and startup.

Your machine will need:

- Power distribution

- A controller with I/O modules

- Logic (programming) for operation

- A safety circuit

- Operator interface for visualization, alarming, and control.

Your machine may need:

- Sequencing

- Product specific control

- Temperature control

- Filling control

- VFD control

- Servo control

- Product inspection

- Coordination with other equipment

- Data reporting

TAI provides your machine with the flexibility, consistency, dependability, and ease of operation needed in today’s competitive manufacturing environment.

Packaging Line Integrations

Packaging Lines often encompass machines from different vendors. These machines need to integrate into a smooth running, connected, complete operation. We provide the services to bring the disparate pieces together into one seamless whole.

Your production line may include:

- De-palletizers

- Conveying systems

- Filling machines

- Labelers

- Cappers

- Security Sealers

- Cartoners

- Case Erectors

- Case Packers

- Gluers and Tapers

- Palletizers, Banders, and Stretch Wrappers

Personnel & Equipment Safety

Our team of experienced safety experts can assess the risks of your equipment and design the appropriate remediations to bring the risks down to acceptable levels. We work with safety, production, maintenance, and engineering personnel to find the safest and most workable solutions.

Our safety service offerings include:

- Risk Assessment

- Risk Elimination

- Lockout/Tagout Design

- Safety circuit design to meet required safety level

- Machine Guarding with controlled access

- Access Doors with Safety Switches

- Trapped Key Access Control

- Light Curtains

- Two-hand Safeties

- Safety Mats

- Area Scanners

- Verification

- Validation

Don’t wait until you have a recordable injury accident to bring your production equipment into a safe state for the valuable people that work for you.

We can help now.